Power converters - a new paradigm

It’s time to say goodbye to bulky, monolithic hardware. Whether it’s supercomputers, satellite constellations, energy grids, communication networks, or even nuclear power plants, smart distributed systems are in. In fact, a manifold of identical components often outperforms the heavy tech of the past. Fast, scalable, resilient, energy-efficient, and cost-effective - the advantages and benefits of nested systems are numerous.

Power converters are no longer an exception to the rule. BrightLoop’s converter technology builds on nested topology of small converter cells that can be replicated ad infinitum to manage MW power. It offers modularity, scalability, and an unprecedented power density of up to 35 kW per kg, or 60 kW per liter.

Defying the limits of power conversion

Backed by our long-standing expertise of tailor-made power conversion solutions, we have developed a platform designed to meet the electrification requirements of the most demanding applications, whether industrial or e-mobility related. Drawing on the most recent semiconductor technologies, we anticipate solutions that will play a pivotal role in driving the energy transition.

Our extensive range of off-the-shelf products is the result of in-depth knowledge and expertise in power electronics, mechatronics, and software control. Through multiple design iterations, we make the most of every single component to deliver powerful, ready to use converters. Our products are flexible, compact and lightweight, raising new standards in energy efficiency.

BrightLoop nested topology: connecting flexibility to standardization

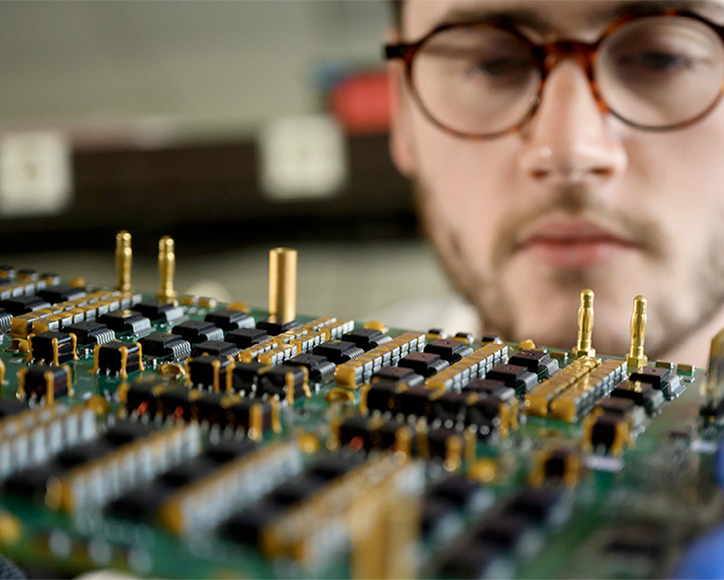

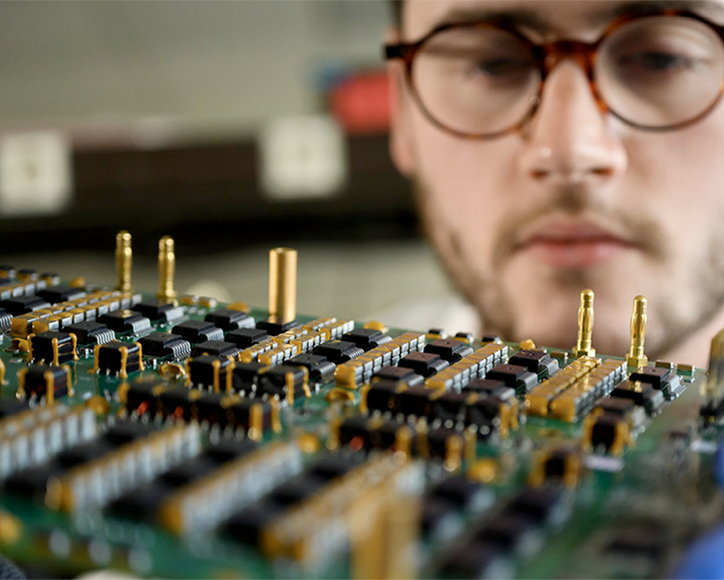

The cellular power conversion topology of our converters can host multiple independent programmable power paths, functioning as sub-converters. Channels, built of identical switching cells and high-performance passive components, are grouped together into a power path and are operated in parallel by the control system. Each power path supports bidirectional power flows for AC-DC or DC-DC conversion. Wide-bandgap semiconductors — SiC for high voltage systems and GaN for low voltage — form the active core of this nested structure.

The cellular topology reduces space requirements by distributing all electronic, thermal and computational resources across multiple identical elements, which can operate either in a decentralized or centralized manner. Project-proven implementations include up to 16 modules stacked in parallel to achieve 10 MW of total power. Each module can be controlled as a single entity through an overlay of distributed intelligence. This architecture enables true N+1 redundancy to create fault tolerant systems.

Modular and compact, our converters adapt to diverse applications, offering clients flexibility to configure their system layout according to their needs and preferences. This flexibility extends to downsizing the required volume or integrating additional functionalities for enhanced performance.

Embedding the latest wide-bandgap semiconductor technologies

We stay attuned to the latest semiconductor advancements. At the microscale, our low voltage systems embark the most efficient GaN HEMTs (Gallium nitride high-electron-mobility transistors) while our high voltage systems house SiC MOSFETs (Silicon carbide metal–oxide–semiconductor field-effect transistors). SiC- and GaN-based power electronics offer superior performance and size reductions compared with conventional semiconductor devices.

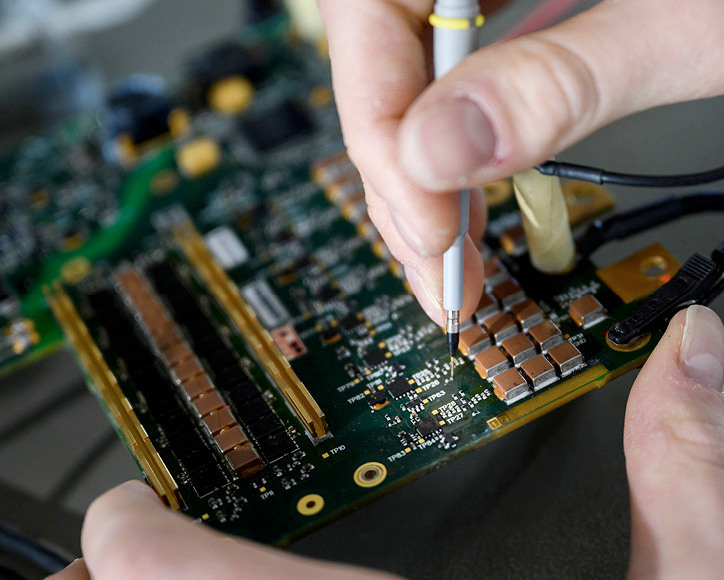

Our engineering teams leverage the intrinsic advantages of wide-bandgap semiconductor technologies. They are thus able to effectively increase power density, optimize thermal dissipation and reduce switching and conduction losses as well as reverse recovery time. We consolidate our technology advance through partnerships with leading electronic component manufacturers, offering our clients the most efficient power conversion systems available.

The BrightLoop software platform: master craftsmanship

Our nested architecture is orchestrated precisely and smoothly by advanced control and switching techniques. Each module features a dedicated microcontroller which distributes resources among channels in real-time and monitors each power path independently, ensuring tasks are executed with optimal efficiency. For modules operating in parallel, a communication layer is added to facilitate the management of large arrays.

Our advanced software platform offers versatile controls capable of adapting seamlessly to diverse operating conditions.

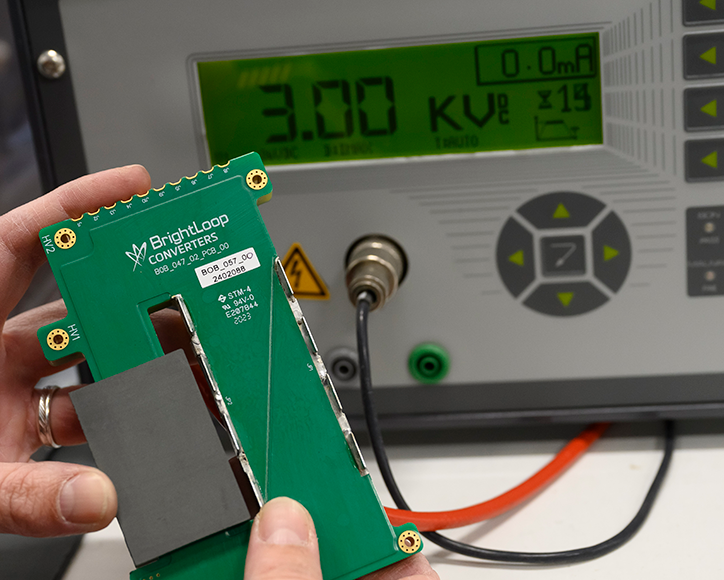

Galvanic isolated transformers

Some operating conditions require galvanic isolation of a converter’s input and output stages. Our R&D team has developed a revolutionary approach to DC-DC galvanic isolation, using transformers that operate at high frequencies up to 300 kHz. This innovation results in end-to-end AC-DC conversion systems capable of efficiently handling MW-class demands within a package size 5,000 times smaller than conventional grid-frequency transformers.

This groundbreaking achievement marks an industry first, overcoming the constraints of space and weight associated with bulky transformers and unlocking new opportunities for remote and offshore applications.