Paris – BrightLoop’s central hub

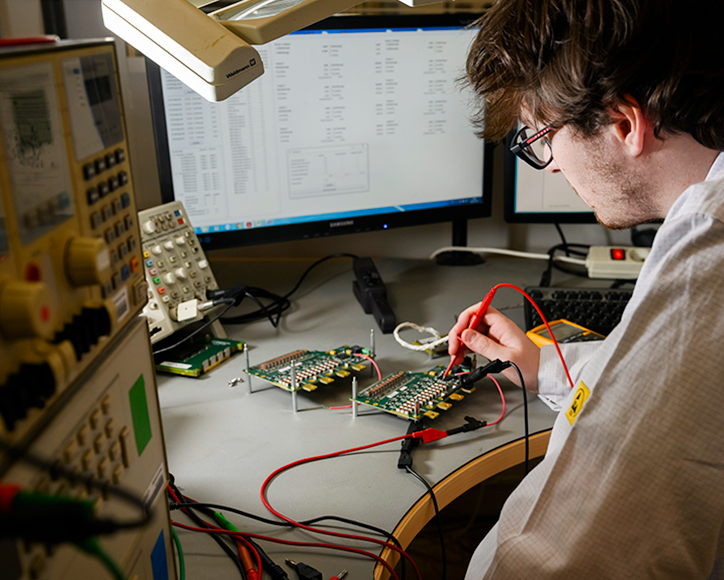

BrightLoop’s headquarters and R&D center are situated in Paris, the organization's central hub. Here we consolidate all activities from design to prototyping, testing, and low-volume production of a few tens of units per year. The expertise and capacity of our Paris team ensures swift responsiveness and accelerates project development, enabling us to deliver solutions to our clients' needs promptly.

Through research and development work, our engineering team actively identifies emerging technology trends and growth areas and develops advanced solutions tailored to the needs of future electrification applications.

Lannion – A scalable industrial facility

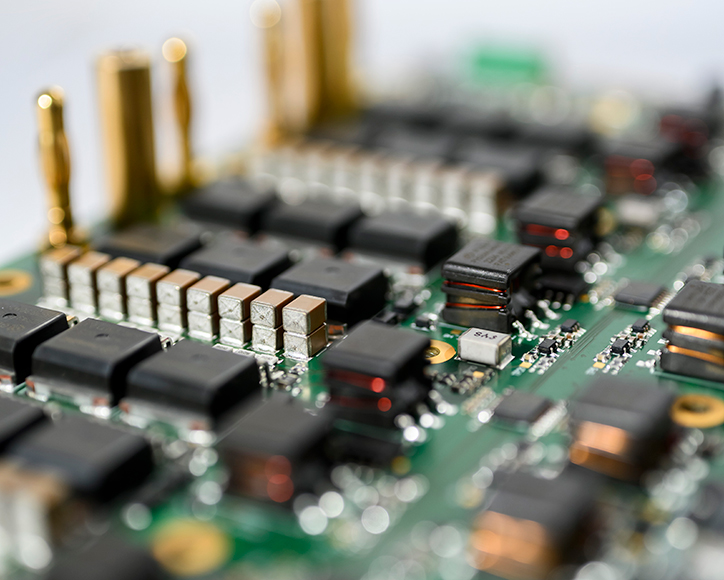

Our industrial facility is located in Lannion, in northern Brittany. The Lannion Technopole, historically known as the French "Telecom Valley," today attracts skilled engineers and technicians drawn by the presence of cutting-edge industries specializing in electronics, photonics and biotechnologies.

Our Lannion site industrializes the solutions developed by the Paris team, managing the assembly and testing of pre-series and high-mix low- to mid-volume series. The entire industrialization process is structured according to the New Product Introduction (NPI) process management methodology. Annual production capacity amounts up to 5,000 converters.

Dourdan – Prototyping and machining

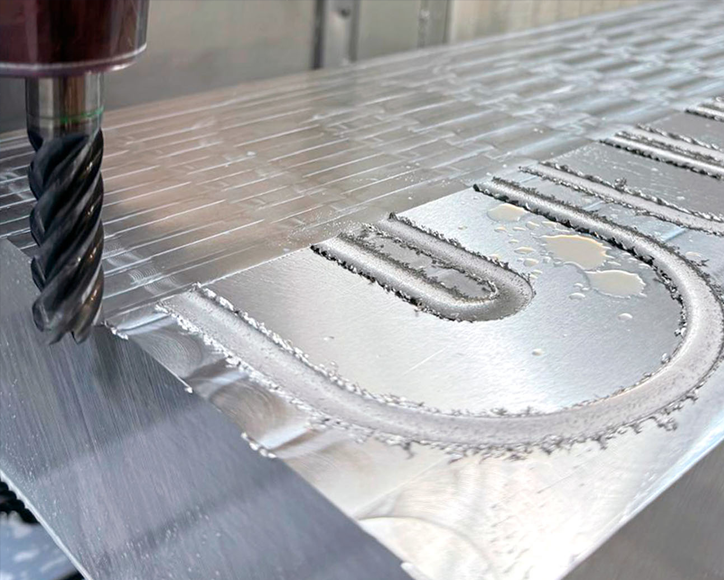

BrightLoop Mechanics is located in Dourdan, south of Paris. The subsidiary is a main supplier of machined parts to BrightLoop, particularly high-precision converter housings, a critical component of BrightLoop’s high-power, high-density devices.

The company owns a unique friction stir welding (FSW) process and proprietary tools, integrated into a machining tower. This allows precision welding to be performed in the same setup as machining. The process enables production of converter housings with integrated 3D cooling circuits that offer unparalleled precision, ruggedness and compactness.

Globalized production strategies

Drawing from an inventive manufacturing framework, our flexible and modular structure mirrors the topology of our product design, enabling agile production strategies. We like to say that our industrial facility is a gigawatt factory unit model, which can be replicated globally to meet the growing demand for high-quality, high-power converters at a local level. Furthermore, to scale up production volumes, we have partnered with carefully selected EMS (Electronic Manufacturing Services) providers, ensuring full manufacturing and testing under BrightLoop’s close oversight. Involved in a worldwide supply chain, we closely collaborate with key local and international players to deliver our products to every corner of the globe.

With a workforce growth of more than 50% in 2023, our team now comprises 70 employees, with 40 based in Paris and 30 in Lannion.